Safe isolation is a critical safety procedure used by electricians and maintenance workers to ensure that electrical equipment or circuits are de-energised and safe to work on. The purpose is to prevent electric shock, arc flash, or other electrical injuries when performing installation, maintenance, or inspection tasks.

Following a formal, structured isolation process ensures compliance with regulations such as Electricity at Work Regulations 1989 and the BS 7671 (IET Wiring Regulations).

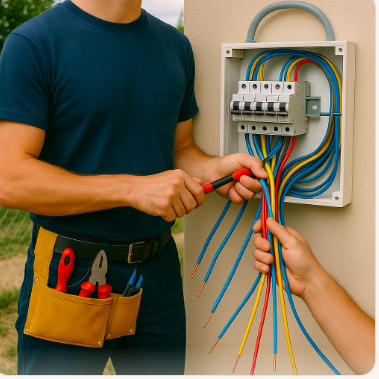

Tools and Equipment Required

To carry out safe isolation, you’ll need:

- Lock-off kit (including padlock, lock-off device, and warning tag)

- Proving unit (to test voltage indicators)

- Approved voltage indicator (e.g. two-pole tester)

- Screwdrivers and PPE (gloves, safety glasses)

Step-by-Step Safe Isolation Procedure

1. Inform and Identify

Before starting:

- Inform anyone affected (e.g. building users, other trades) that power will be isolated.

- Identify the correct circuit or equipment you intend to work on.

- Check circuit diagrams, schedules, or test results to confirm the source.

Never rely solely on labels or assumptions—always verify!

2. Switch Off and Isolate

Once identified:

- Switch off the circuit using the local isolator, switch, or circuit breaker.

- Isolate the source at the main consumer unit, distribution board, or isolator switch.

- For plug-and-socket systems, remove the plug (and secure it if necessary).

Use only dedicated isolation points that disconnect both live and neutral conductors.

3. Apply Lock-Off Device and Warning Tag

- Fit a suitable lock-off device to prevent the circuit from being accidentally re-energised.

- Secure it with a padlock, ideally keyed uniquely to the person working on the circuit.

- Attach a warning tag with your name, date, and contact details to clearly indicate maintenance work is underway.

Only the person who applied the lock should remove it. Never share padlock keys.

4. Test Your Voltage Indicator

Before testing the circuit:

- Prove your voltage tester is working correctly by testing it on a proving unit or a known live source.

- This ensures your device gives accurate readings and hasn’t failed or become faulty.

5. Test the Circuit for Dead

Using your proven voltage tester:

- Carefully expose the conductors (e.g., live, neutral, earth) at the point of work.

- Test between live and neutral, live and earth, and neutral and earth.

- Confirm no voltage is present (should read 0 volts or indicate dead).

If using a two-pole tester, hold probes steadily and check at several points to ensure reliable results.

6. Prove the Tester Again

After testing the circuit is dead:

- Use your proving unit once more to confirm the voltage tester is still working.

- This step confirms that your earlier “dead” reading wasn’t due to tester failure.

7. Begin Work Safely

Now that the circuit is verified as isolated and dead:

- Proceed with your work, maintaining awareness of any other nearby live circuits.

- Use insulated tools and wear appropriate PPE as an added precaution.

Key Safety Tips

- Never assume a circuit is dead—always test first.

- Do not rely on neon screwdrivers or non-contact voltage pens; they are not suitable for confirming dead.

- Only use voltage indicators that comply with GS38 (HSE Guidance Note for safe testers).

- Always lock off isolation points—do not just label or turn off.

When to Use Safe Isolation

Safe isolation should be carried out:

- Before electrical installation or repairs

- During inspection and testing

- When replacing accessories like sockets, switches, or lights

- Before maintenance of plant or machinery

Whether in a domestic, commercial, or industrial setting, this procedure protects workers and helps organisations comply with legal safety standards.

Conclusion

Safe isolation is a life-saving process that every competent electrical worker must understand and apply. By systematically identifying, isolating, locking off, and proving dead, you reduce the risk of injury or death due to accidental energisation. Always use approved tools, follow proper procedures, and never take shortcuts—safety always comes first.

Recent Comments